Oil & Gas

TMS offers a vast array of services for the oil & gas industry including manufacturing of certain API products, servicing and parts manufacturing of various rig equipment and downhole tools.

Rig equipment

- Main and auxiliary engine - re-conditioning of engine parts

- Mast raising and sub-structure cylinders - complete re-conditioning and manufacturing

- Crown and travelling blocks - complete parts manufacturing including API 8C sheaves

- Top drives - parts manufacturing including quill shaft, gears and hydraulic systems

- BOP hoisting and travelling systems - re-conditioning and parts manufacturing. Capable of manufacturing complete assembly parts

- Mud pump - parts re-conditioning including crankshafts, connecting rods and fly wheel

- Draw works and rotary table - parts manufacturing including main shaft, winch drum and gears

- Auxiliary pumps - parts and complete manufacturing including casings, impellers, shafts and white metal

bearings - Hydraulic systems - Design, build and commissioning of various rig hydraulic systems including, HPUs, power packs, spooler systems, skidding systems, hoisting systems. Conversion of various manually operated handling systems into hydraulic operated ones

- Other services - Fabrication of tool baskets, in-situ machining and various rig fabrication parts

- Raw material supply - Alloy steels including 4140, 4145 and 4330V both in round bars and tube form. Deep-hole drilling for various ID requirements and honing capabilities

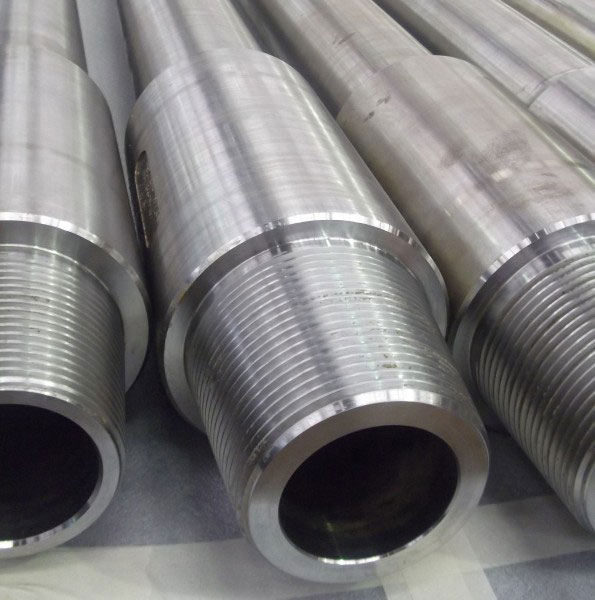

Drilling and downhole tools

- Casings and tubing - manufacturing and threading as per API 5CT. Accessories include pup joints, couplings and crossover joints including machining of various premium connections such as VAGT, VA superior, TPCQ and TMKPF. Copper plating of box connections to prevent galling

- Drill pipes, crossovers and subs - threading rotary shouldered connection as per API 7-1 and various other premium connections such as Hilong. Manufacture of various types of crossovers and subs

- Drilling jars and shock tools - complete parts manufacturing including mandrels, housings, cylinders, spring barrels, pistons, collets and others. Reconditioning of various housings and cylinders through HVOF metal spray and electro plating (Chrome and Sulphamate Nickel)

- Mud motor rotors - complete reconditioning of rotors including, re-coating, threading connections, stub welding and catcher repairs

- LWD and MWD parts - re-conditioning through built up and protective spray

- Completion tools – parts manufacturing with services include heat treatment, coatings and specialized machining

-

Oil & Gas

-

Oil & Gas

-

Oil & Gas

-

Oil & Gas